Interior deck system for the Desiro ML/ÖBB

Following the development of the interior deck system for the Desiro ML Mittelrheinbahn and the Desiro ML Brüssel at TC and its subsequent delivery, the interior deck system for the Desiro ÖBB is now being manufactured at TC. The various systems are based on pultruded profiles made of glass fibre-reinforced plastic produced by Exel Composites in Belgium.

Middle deck

The middle deck profile is 1,038 mm wide. Each middle deck is fitted with tongue and groove elements and gluedon reinforcement profiles. CNC machining is performed on modern 5-axis CNC machines at TC.

Low-floor / high-floor haunches

Low-floor and high-floor haunches are also CNC-machined and fitted with glued tongue and groove elements in accordance with DIN 6701. These allow tolerance compensation to be achieved in relation to the shell.

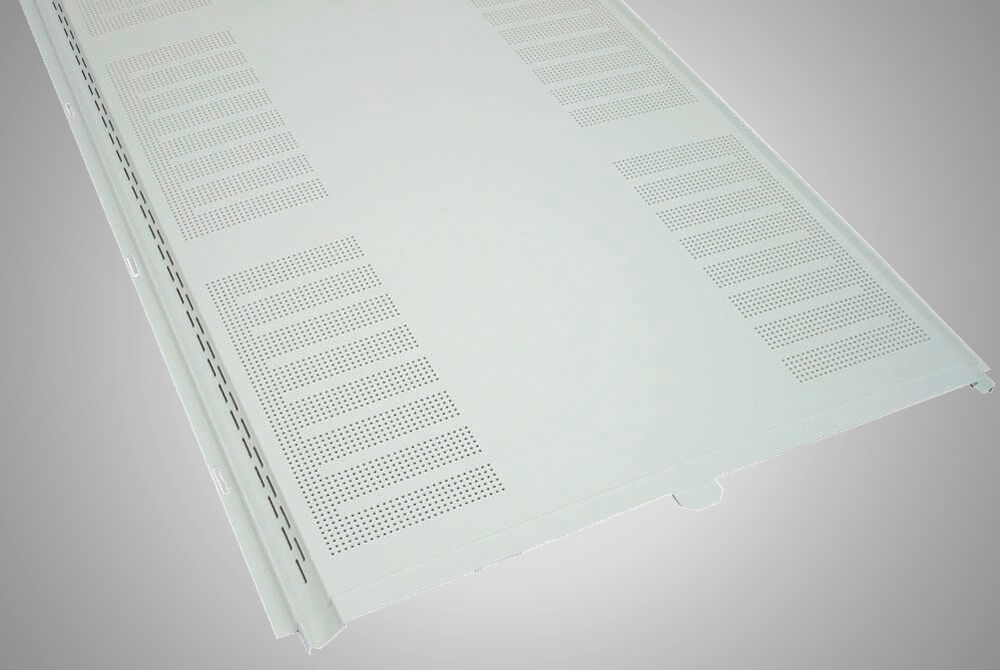

Lateral interior deck

The lateral interior deck extends into the haunches, while obscuring the screw points at the same time. Like all of the profiles, it meets the fire protection requirements according to EN 45545.

Middle deck profile (3D)

TC also handles special components like these 3D middle decks in the vicinity of the doors. The 3D laminate is glued into the pultruded profile. After painting, it appears to be a single piece.

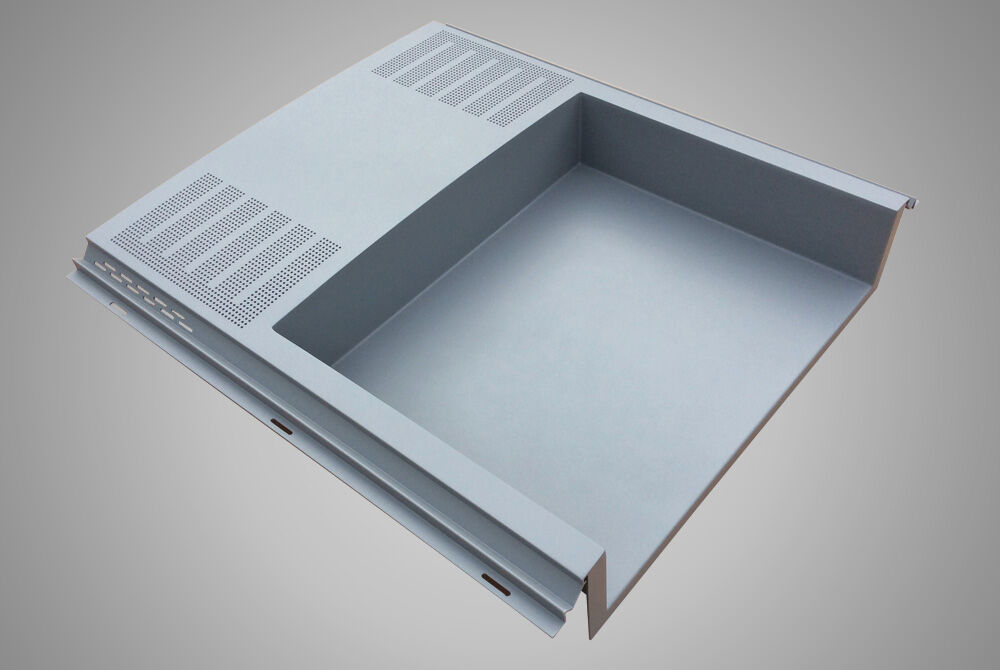

Aluminium load-bearing system for interior deck profiles

What TC achieves as a system supplier can be clearly seen from the aluminium load-bearing system that holds the GRP interior deck profiles. It is also CNC-machined and assembled at TC. Everything from a single source.

Pre-defined logistics modules

Siemens Rail Systems has been provided with various products for the Desiro ÖBB, which are sorted, fully packaged, and delivered in pre-defined logistics modules. 17 logistics modules comprising a total of

564 different items are packed for each train.

Bonding in accordance with DIN 6701 (Class A1)

We have been continuously expanding our expertise in the field of adhesive technology for years. A number of European Adhesive Engineers (EAE, DVS-EWF 3309), European Adhesive Specialists (EAS, DVS-EWF 3301) and European Adhesive Bonders (EAB, DVS-EWF 3305) have been trained in the process.

Cutting-edge technology, vast expertise

When manufacturing pultruded profiles, the fire protection properties can be adapted to your requirements. We produce extremely high-quality surfaces that can then be painted for a textured or smooth finish. We machine the profiles with high precision using our modern 5-axis CNC machinery.

Certified quality management

Every TC component is developed in accordance with the applicable requirements and standards. We conduct careful testing and documentation as a matter of course. Certification according to DIN EN ISO 9001:2015 confirms that our quality management is sound. We also hold IRIS certification in accordance with ISO/TS 22163:2017 for our customers in the rail vehicle sector.

Are you facing similar challenges?

Let's talk about possible solutions.

Roof panels for the Sprinter Lighttrain in the Netherlands