Side panel casing components for the TALENT local train

TC supplied side panel casing components for the TALENT local train, manufactured by Bombardier Transportation in Talbot. These components were manufactured on the basis of nine different pultruded profiles. All of the components – the GRP profiles and other components made of SMC pressed parts, EPDM covers, stainless steel and aluminium components – were designed, machined and bonded together at TC. This meant that the customer was supplied with ready-to-paint finished parts.

Bonding in accordance with DIN 6701 (Class A1)

We have been continuously expanding our expertise in the field of adhesive technology for years. A number of European Adhesive Engineers (EAE, DVS-EWF 3309), European Adhesive Specialists (EAS, DVS-EWF 3301) and European Adhesive Bonders (EAB, DVS-EWF 3305) have been trained in the process.

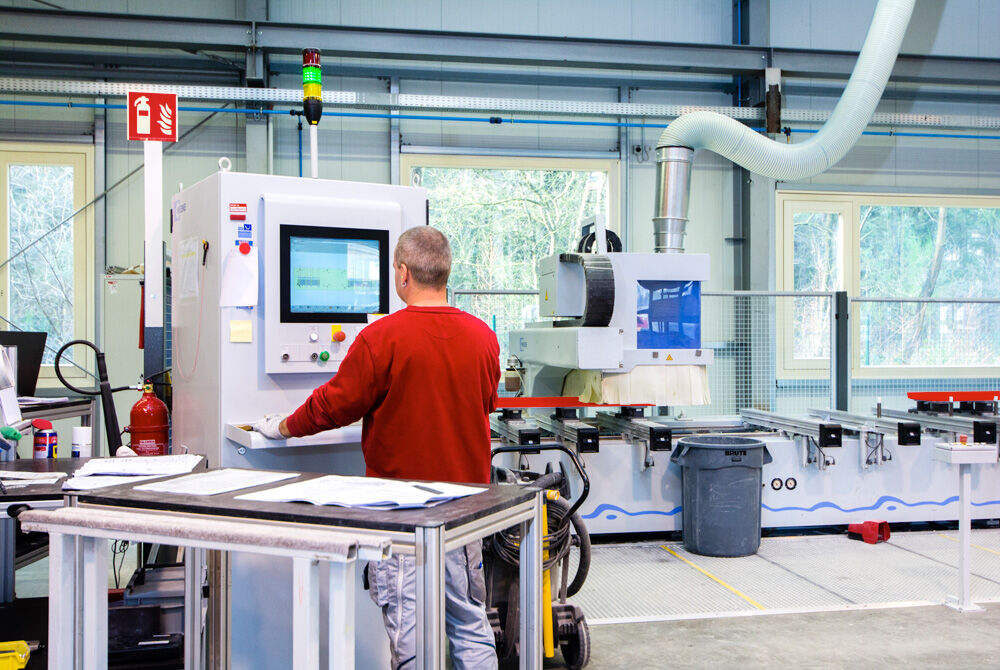

Cutting-edge technology, vast expertise

When manufacturing pultruded profiles, the fire protection properties can be adapted to your requirements. We produce extremely high-quality surfaces that can then be painted for a textured or smooth finish. We machine the profiles with high precision using our modern 5-axis CNC machinery.

Certified quality management

Every TC component is developed in accordance with the applicable requirements and standards. We conduct careful testing and documentation as a matter of course. Certification according to DIN EN ISO 9001:2015 confirms that our quality management is sound. We also hold IRIS certification in accordance with ISO/TS 22163:2017 for our customers in the rail vehicle sector.

Are you facing similar challenges?

Let's talk about possible solutions.

External casing components for urban buses and longdistance coaches